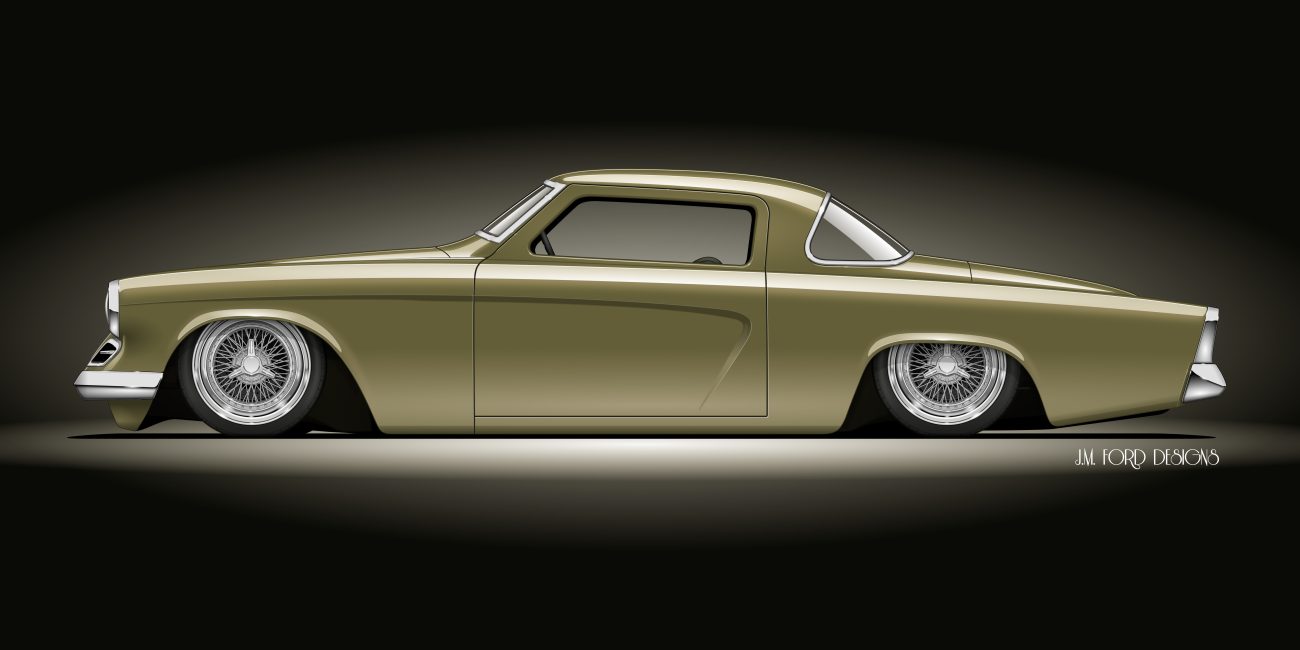

Hot Rod

Channel Your Expression

Express yourself

When you want to express yourself, the only limitation should be your imagination.

We have the experience and creative ability to translate your dreams into reality.

From an initial idea or sketch we can draw up 3D CAD designs at the concept stage and follow through to making the rolling art in metal.

Your vision, your canvas.

We appreciate a true individual – that’s because we do things our own way too. No production line. No automated factory. Just pure engineering talent, a love of what we do, and tea brewed so strong you can stand a spoon up in the cup.

You might not see the exact style you’re looking for on our website. That might be because until now, it’s only existed in your head. Let us help you get it out of there and ON TO THE ROAD.

Experience

Hot Rod & Custom Gallery

Add a classic, unique look to your Hod Rod or custom with Turrino's custom made wire wheels

Turrino

Our History

From humble beginnings to worldwide distribution

Workshop opens

Steve Hopkins begins repairing wire wheels at Langley Mill, Macclesfield, Cheshire trading as 'Specialised Automobile Services'. Many steel rims and wheel centres are no longer available so he starts to manufacture them himself.

1980

First Borrani restorations

Steve begins to restore Borrani alloy rim wire wheels

1982

Turrino alloy rims are first made

The first Turrino alloy rim wire wheels are made in Macclesfield. The early ones are mainly for Aston Martins and Ferraris and are individually numbered. Our records show 57 Turrino alloy wire wheels completed by the end of 1994

1993

The 1000th Turrino wire wheel

Supplied to Hall & Fowler (now Hall & Hall) of Bourne for a Ferrari single seater in May 2000

2000

Turrino Wheels Ltd is born

Will Tomkins buys the business and moves to a new worksop in Kings Cliffe, Northamptonshire. Now trading as Turrino Wheels Ltd.

2009

International Patents granted for split rim wire wheels

We are the only manufacturer of split rim wire wheels in the whole world

2012

First Turrino rims made from thick wall alloy tube

This enables us to machine the inner diameter of the rims and to control the rim profile as desired.

2014

Expansion and addition of new large machine shop

7 additional CNC machines enable more efficient production and mean every operation is done in-house.

2015