Quality, Pristine, Unique

Turrino Alloy Wire Wheels

Made in England

Hand built to order for any car Turrino’s Alloy Wire Wheels stand apart from any other wire wheel on the market through quality craftsmanship, pristine finishes and unique custom options. Light weight construction and build techniques improve performance, road handling and steering efficiency enhancing not only the look of your vehicle but also the driving experience.

Acceleration, Steering, Handling

Alloy Wire Wheel Performance Benefits

Turrino alloy wire wheel rims are typically 3-5kg lighter than steel equivalents.

Acceleration

Acceleration – Is significantly improved due to the reduced rotational moment of inertia. A 4Kg saving on each rim (16Kg per car) will have the same effect on acceleration as lightening the car by 80-160kg! The rule of thumb is that each 1kg saved at the rim equates to 5-10Kg of static (car) weight. Remember – the moment of inertia is a product of the mass x the square of the radius so the bigger your wire wheel diameter & the wider the rim – the more you gain.

Steering

More precise steering input & better turn-in due to significantly reduced gyroscopic effect of a directional change.

Road Holding & Handling

Reduced un-sprung weight means the spring/damper combination works more effectively to keep the tyres in contact with the road.

This is why alloy rims have been used on all top line competition and sports car since the 30’s. We have received dozens of unsolicited reports from owners who have been astonished at the difference our wheels have made to their driving experience of their road cars. All this combined with stunning look. Stainless spokes & wheel centres, Tubeless sealing for further weight saving, all supplied as options. Each wire wheel hand built in England to suit your car, supplied to leading historic racers and restorers worldwide for the last 27 years.

Weight

Turrino alloy wire wheel rims are typically 3-5KG lighter than steel equivalents

Steering

More precise steering input & better turn-in

Handling

Reduced un-sprung weight works to keep the tyres in contact with the road.

Driving Experience

The combined benefits add up to deliver an incredible driving experience

Spun, Rolled, Extruded & offsets

Tech Specs

Standard spun rim sizes

| Diameter (inches unless otherwise stated) | Width (inches) |

| 10 | 3.5 |

| 12 | 3.5 |

| 14 | 5.5, 6.5, 7 |

| 15 | 3.5, 4, 4.5, 5, 5.5, 6, 6.5, 7, 8, 9 |

| 400 mm | 4.5, 5, 5.5, 6 |

| 16 | 4, 4.5, 5, 5.5, 6, 6.75, 7.5 |

| 17 | 5, 5.5, 6.5 |

| 18 | 5, 6, 7, 8 |

Rolled and extruded rim sizes

| Rolled and extruded rim sizes | |

| Diameter (inches unless otherwise stated) | Width (inches) |

| 17 | 3, 3.5, 4, 4.5 |

| 18 | 3, 3.5, 4, 4.5 |

| 19 | 3, 3.5, 4, 4.5 |

| 20 | 3, 3.5, 4, 4.5 |

| 21 | 3, 3.5, 4, 4.5 |

Sizes not listed above can either be:

- Machined from solid aluminium billet. In this case the rims will always be without dimples.

or

- Made using our patented SPLIT RIM wire wheel designs which can be made with or without the rim bolts being visible.

ALL DIAMETERS from 10 to 22 inches

ALL WIDTHS from 5 to 14 inches

Rim Measurement & Offset

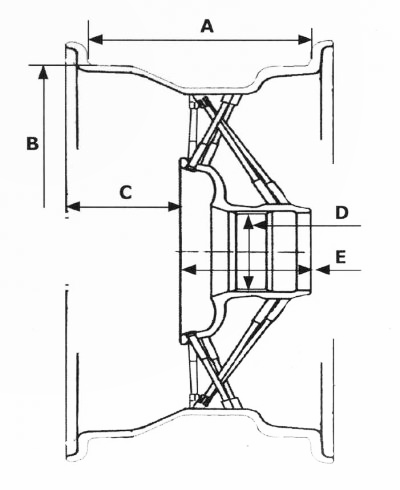

Rims are measured as A x B on the rim diagram.

Before the second World War width was quite often measured as the full width of the rim which can lead to confusion. For example an Alfa Romeo wheel described in their literature as 4 x 19 is what we now classify as 3 x 19.

We specify the offset of centre lock wheels by the backspace measurement ‘C’ on the diagram.

ET is another way to specify offset but is applicable to bolt on (not centre lock) wheels, being measured from the hub mounting face to the centre of the wheel rim.